Side Roll Irrigation

The Side Roll features an aluminum pipe mounted on wheels, ensuring easy operation. It's designed with convenience in mind, with no moving parts during irrigation, making it ideal for various field layouts.

Dealers Who Have Trusted Us

What is new in IRRILINE Hand Roll Irrigation Systems?

- Overview

- Features

- Operation

- Specification

- Performance

- Spare Parts

- Overview

- Features

- Operation

- Specification

- Performance

- Spare Parts

The IRRILINE Side Roll (a.k.a. Motoroll, Roll Line, Wheel Line, Wheel Move) is a mechanized sprinkler irrigation system, capable of operating well in most soils and irrigating most crops, except tall crops such as sugar cane and corn, and it can operate up to 7% slope.

Side Roll is an ideal choice for modern technical irrigation in any location, especially in areas with high labor costs. The system can easily be operated and maintained, and there is no need for highly skilled technical support personnel. The Side Roll is an efficient and economical system in small fields, and the cost per hectare/acre is relatively low.

The Side Roll consists of rigidly coupled aluminum pipes, mounted on large wheels with the pipe acting as an axel. The drive unit contains an 8 HP gasoline engine and a transmission with a reverse gear.

Irriline has 4″ and 5″ Side Roll that can be up to 500 m in length. Each 12 m has one sprinkler and operating pressure of about 4 atmosphere (60 psi) at the inlet.

To learn more about Side Roll, please see Features, Specifications, Operation, and Performance.

Side Roll New Features

What is new in IRRILINE Side Roll Irrigation Systems?

- Newly fixed manometers on both ends of Irriline Side Roll System, enabling to Measure the correct pressure at any time.

- The New Side Rolls are with Hot Dip Galvanized chassis

- Wheels: All wheels are made by hot deep galvanized

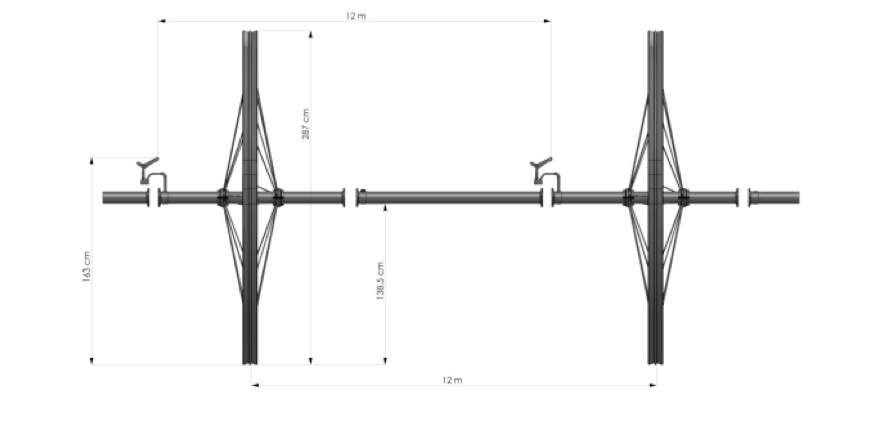

- Irriline now manufactures Side roll with 287 Cm wheels for higher crop irrigation with 150 cm Height

IRRILINE Hand Roll Wheel’s

is available in Different heights.

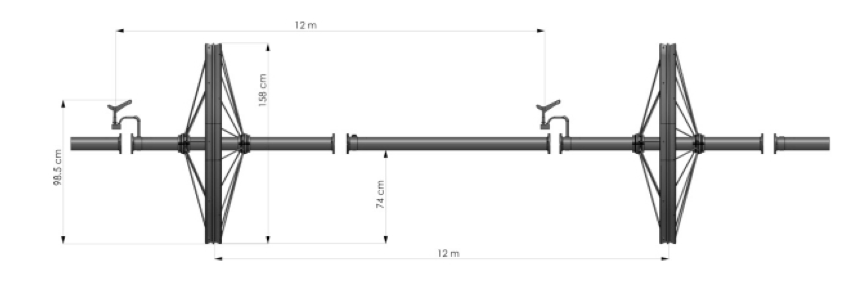

- 158Cm Wheels

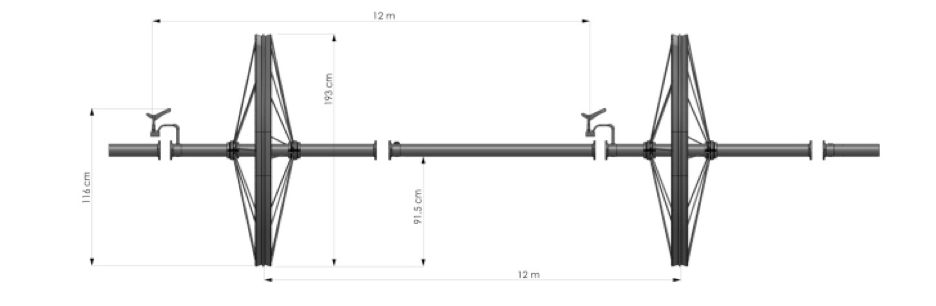

- 193Cm Wheels

- 287Cm Wheels

Covering Area

Irrigating area covered by a Hand Roll Irrigation System is depends on length of farm, soil and climate. Refer to the data table below:

| Hand Roll Length (M) | Farm Dimension (M) | Covering area (Hectare) | Irrigating time in each position | Irrigating position OR Movement per Day |

| 204 | 212 x 400 | 8.50 | 4 to 5 Hours | 3 to 4 Times |

| 216 | 224 x 400 | 9.00 | 4 to 5 Hours | 3 to 4 Times |

| 228 | 236 x 400 | 9.50 | 4 to 5 Hours | 3 to 4 Times |

| 240 | 248 x 400 | 9.90 | 4 to 5 Hours | 3 to 4 Times |

| 252 | 260 x 400 | 10.40 | 4 to 5 Hours | 3 to 4 Times |

| 264 | 272 x 400 | 10.90 | 4 to 5 Hours | 3 to 4 Times |

| 276 | 284 x 400 | 11.40 | 4 to 5 Hours | 3 to 4 Times |

| 288 | 296 x 400 | 11.80 | 4 to 5 Hours | 3 to 4 Times |

| 300 | 308 x 400 | 12.30 | 4 to 5 Hours | 3 to 4 Times |

| 312 | 320 x 400 | 12.80 | 4 to 5 Hours | 3 to 4 Times |

| 324 | 332 x 400 | 13.30 | 4 to 5 Hours | 3 to 4 Times |

| 336 | 344 x 400 | 13.80 | 4 to 5 Hours | 3 to 4 Times |

| 348 | 356 x 400 | 14.30 | 4 to 5 Hours | 3 to 4 Times |

| 360 | 368 x 400 | 14.70 | 4 to 5 Hours | 3 to 4 Times |

| 372 | 380 x 400 | 15.20 | 4 to 5 Hours | 3 to 4 Times |

| 384 | 392 x 400 | 15.70 | 4 to 5 Hours | 3 to 4 Times |

| 396 | 404 x 400 | 16.20 | 4 to 5 Hours | 3 to 4 Times |

Features of Side Roll

Side Roll: One of the safest and most reliable mechanized sprinkler irrigation systems available.

The Irriline Side Roll is easy to understand, operate and maintain, and there is no need for complex technical support for this mechanized sprinkler irrigation system.

Pipe

Rigidly coupled high quality 100 mm (4″) diameter extruded aluminum tubes, mounted on large wheel with the pipe acting as an axel. Pipes are about 12 m (40′) long and 1.8 mm (0.071″) thick. On each side of the drive unit, pipes are about 6 m (20′) long and 2.2 mm (0.087″) thick, providing more strength and stability. The system can be up to 490 m (1608′) in length, but variation in length can be ordered. Our heavy-duty extruded aluminum pipes meet or exceed ASAE (American Society of Agricultural Engineers) standards for aluminum sprinkler irrigation tubing (S263.3).

Mover Unit

The Irrican Motoroll is repositioned by a hydraulic power mover. The mover unit, located in the center of the aluminum line, combines an 8 HP air-cooled gasoline engine, hydraulic system with motors, hoses and gears, and heavy duty frame and high quality steel chain for easy movement and alignment.

Sprinklers

Sprinklers, from the premier manufacturers of the industry, are mounted on self-levelers, to keep the sprinklers always right side up, and have protection cups to prevent clogging.

Couplers

Made of high quality die cast aluminum, couplers are designed for easy and quick line assembly and take down.

Drain Valves

Located on each female coupler, drain valves automatically drain the pipe when the water is turned off, and seal when the water is turned on.

Note: The system must be completely drained before repositioning.

End Plug

One-piece die cast flush plug with splash guard. It is easy to clean any debris and trash with the manual control valve.

Wheels

Heavy-duty hot dip galvanized steel wheels with 3 mm cleats provide great strength and easy movement. There are different sizes to choose from: 1.47 m (58′), 1.93 m (76″), and 2.85 m (112″) in diameter, providing more flexibility for various crop clearances.

Flexible Hose

Special long-lasting 100 mm x 6 m (4″ x 20′) UV-resistant flexible hose is used to connect the Motoroll to the supply line (mainline). Both end-feed and center-feed are available, depending on the location of the supply line and the length of the system.

Stabilizer

Strong stabilizers are available for the long term parking of the Motoroll and windy conditions (optional).

Side Roll is an aluminum pipe (lateral) mounted on large wheels. The Side Roll irrigates in place (does not move while irrigating) and it is moved from position to position between irrigation runs. An air-cooled gasoline engine provides the required power to move the aluminum sprinkler line across the field. The aluminum pipe is connected to hydrants by a flexible hose. The hydrants are usually spaced every 18 meters (60′) along the supply line (mainline). The supply line may be located along one edge or in the center of the field.

The Side Roll is very simple to operate. When an irrigation run is finished, the operator simply turns off the mainline valve and disconnects the flexible hose. The drain valves automatically drain the pipe due to the reduced pressure. The operator then starts the engine and rolls the pipe to the next hydrant position along the field, reconnects the flexible hose, turns on the water and starts the next irrigation run. The whole operation of repositioning takes about 20 minutes for a single person. When the Side Roll has reached the last position at the end of the field, it is driven back to the starting point for the next irrigation cycle.

Pipe

A. 100 mm x 12 m x 1.8 mm (4″ x 40′ x 0.071″) extruded aluminum pipe with male and female couplers.

B. 100 mm x 6 m x 2.2 mm (4″ x 20′ x 0.087″) extruded aluminum pipe with male and female couplers.

Hose Set

A. 100 mm x 6 m (4″ x 20′) UV-treated flexible discharge hose with standard adapters.

B. 100 mm x 100 mm (4″ x 4″) hydrant opener.

Couplers

B. Female couplers with outlet and flapper.

C. Quality torque coupler clamp and gaskets.

Sprinklers

B. Galvanized sprinkler levelers, risers and elbows.

Mover Unit

A. 8 HP air-cooled gasoline engine Briggs & Stratton.

B. Hydraulic pump and orbit motors ETEN.

C. Quality chains and stainless bolts & nuts.

D. Fiberglass safety cover for engine and hydraulic system.

Wheels

End Plug

Stabilizers

Galvanized stabilizers for windy conditions (optional).

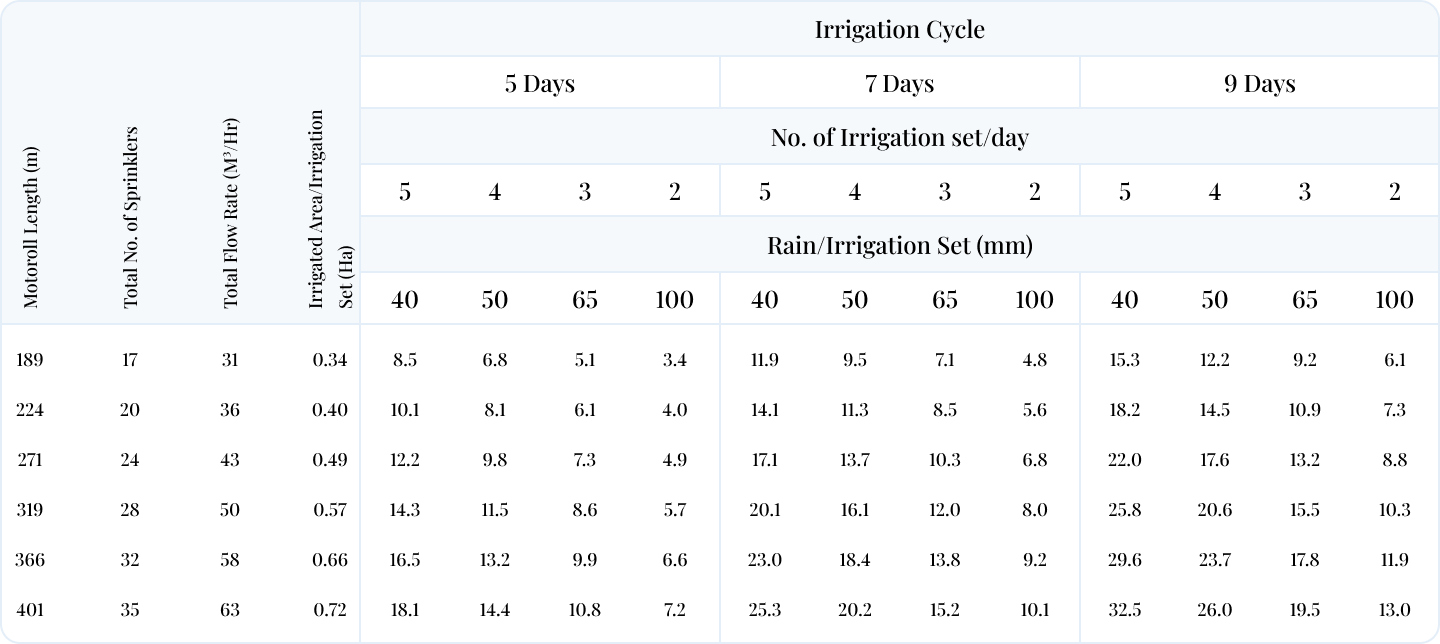

Performance of Side Roll

Area (Ha) irrigated by a Side Roll: for different lengths, application rates, and irrigation cycles

| Parts | Parts Number | Description | |||||

|

|

8 HP Horizontal Shaft Engine |

|||||

|

|

Fiberglass Hood (Horizontal Shaft) |

|||||

|

|

Fiberglass Hood (Vertical Shaft) |

|||||

|

|

Hood Front Support |

|||||

|

|

Sprinkler 3/4″ FC Sprinkler 3/4″ PC |

|||||

|

|

Hook (For Fiberglass Hood I-01-10-018) |

|||||

|

|

Front Clip (For Fiberglass Hood I-01-10-018) |

|||||

|

|

Back Clip (For Fiberglass Hood I-01-10-018) |

|||||

|

|

Complete Chassis |

|||||

|

|

Axle W/ Drive Sprockets |

|||||

|

|

Axle Clamp |

|||||

|

|

Roller Chain |

|||||

|

|

Hydraulic Pump |

|||||

|

|

Hydraulic Control Valve |

|||||

|

|

Hydraulic Filter Screen |

|||||

|

|

Crescent Pin (For Motor Coupling I-01-10-265) |

|||||

|

|

Rectangular Pin (For Motor Coupling I-01-10-265) |

|||||

|

|

Allen Bolt 5 mm Allen Bolt 8 mm (For Motor Coupling I-01-10-265) |

|||||

|

|

Hydraulic Filter |

|||||

|

|

Orbit Motor |

|||||

|

|

Allen Screw Bolt 8 mm (For Orbit Motor) |

|||||

|

|

Flex Coupling |

|||||

|

|

Rubber Connection (between Engine Shaft & Hydraulic Pump) |

|||||

|

|

Aluminum Half Torque Coupler (Male) |

|||||

|

|

Aluminum Half Torque Coupler (Female) |

|||||

|

|

Drain Valve |

|||||

|

|

Rubber Flapper |

|||||

|

|

Stabilizer |

|||||

|

|

Complete Motoroll Hose |

|||||

|

|

Hose to Male End Adapter |

|||||

|

|

Standard Hose Clamp |

|||||

|

|

Galvanized Handle Band |

|||||

|

|

Flush out End Plug End Plug without Outlet |

|||||

|

|

Slip Joint Coupler S. J. C. with Outlet |

|||||

|

|

Hydraulic Flange Adapters |

|||||

|

|

Hydraulic Flange Adapters Gasket |

|||||

|

|

Motoroll Complete Wheels |

|||||

|

|

Half Rims |

|||||

|

|

Motoroll Spokes |

|||||

|

|

Motoroll Cleat |

|||||

|

|

4”X6 m Alum Pipe 4”X12 m Alum Pipe 4”X6 m Alum Pipe w/F&C without Outlet 4”X6 m Alum Pipe w/F&C with Outlet 4”X12 m Alum Pipe with 2 Coupler |

|||||

|

|

Motoroll Hub Half |

|||||

|

|

Torque Coupler Hold Band |

|||||

|

|

Torque Coupler Clamp |

|||||

|

|

¾” Brass Valve |

|||||

|

|

Torque Inlet Tee |

|||||

|

|

½” Cast Iron Tee |

|||||

|

|

Valve Opening Elbow |

|||||

|

|

78 Tooth Bull Gear |

|||||

|

|

Axle Gear |

|||||

|

|

Flanged Gear |

|||||

|

|

Orbit Motor Gear |

|||||

|

|

Hydraulic Hose 60 cm, Orbit-to-Orbit |

|||||

|

|

Hydraulic Hose 45 cm, Orbit-to-Valve |

|||||

|

|

Hydraulic Hose 36 cm, Valve-to-Pump |

|||||

|

|

Hydraulic Hose 43 cm, Filter-to-Valve |

|||||

|

|

Sprinkler Leveler |

|||||

|

|

¾” Galvanized Elbow |

|||||

|

|

Torque Coupler Gasket |

|||||

|

|

Galvanized Pipe Riser |

|||||

|

|

Bolt for Motoroll Wheel 10 mm X 25 mm Bolt for Chassis 10 mm X 60 mm |

|||||

|

|

Gasket (For Slip Joint I-01-20-335/1) |

|||||

|

|

Motoroll Nut 10 mm Motoroll Nut 12 mm |

|||||

|

|

Motoroll Bolt & Nut 12 mm X 120 |

|||||

|

|

Oil Fill Cap |

|||||

|

|

Reducing Elbow |

|||||

|

|

Reducing Elbow ½” |

|||||

|

|

Special Connector ¾” |

|||||

|

|

Normal Connector ¾” |

|||||

|

|

Connector – Male ½” |

|||||

|

|

Connector – Female ½” (Union) |

We Have the Solutions You Need

Get in touch with us today for your sprinkler and irrigation needs. Trusted by farmers since 1988.